English

English-

English

English -

Español

Español -

Português

Português -

русский

русский -

Français

Français -

日本語

日本語 -

Deutsch

Deutsch -

tiếng Việt

tiếng Việt -

Italiano

Italiano -

Nederlands

Nederlands -

ภาษาไทย

ภาษาไทย -

Polski

Polski -

한국어

한국어 -

Svenska

Svenska -

magyar

magyar -

Malay

Malay -

বাংলা ভাষার

বাংলা ভাষার -

Dansk

Dansk -

Suomi

Suomi -

हिन्दी

हिन्दी -

Pilipino

Pilipino -

Türkçe

Türkçe -

Gaeilge

Gaeilge -

العربية

العربية -

Indonesia

Indonesia -

Norsk

Norsk -

تمل

تمل -

český

český -

ελληνικά

ελληνικά -

український

український -

Javanese

Javanese -

فارسی

فارسی -

தமிழ்

தமிழ் -

తెలుగు

తెలుగు -

नेपाली

नेपाली -

Burmese

Burmese -

български

български -

ລາວ

ລາວ -

Latine

Latine -

Қазақша

Қазақша -

Euskal

Euskal -

Azərbaycan

Azərbaycan -

Slovenský jazyk

Slovenský jazyk -

Македонски

Македонски -

Lietuvos

Lietuvos -

Eesti Keel

Eesti Keel -

Română

Română -

Slovenski

Slovenski -

मराठी

मराठी -

Srpski језик

Srpski језик

Why Should You Choose an Aluminum Extrusion Enclosure for Your Projects?

2025-09-26

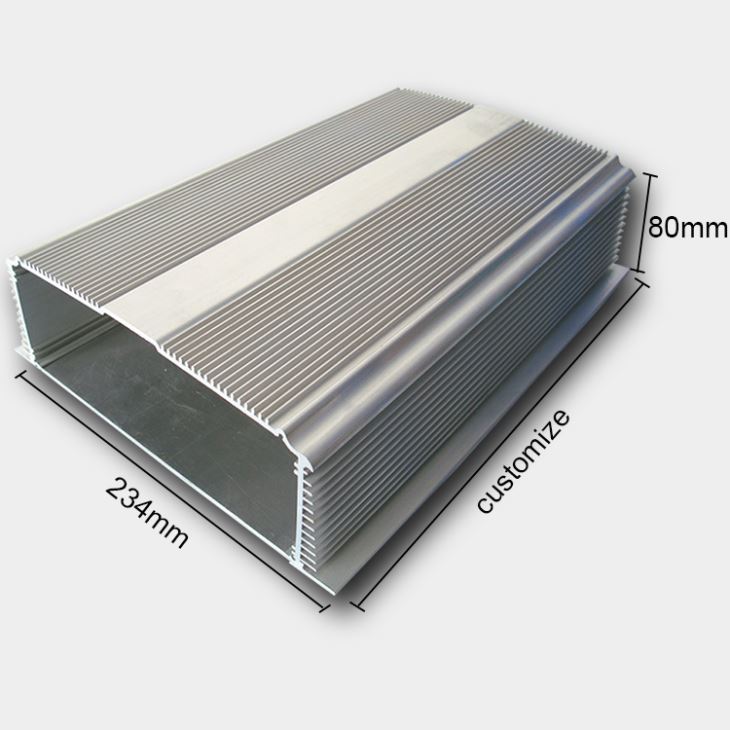

Aluminum extrusion enclosures have become a preferred choice in numerous industries, from electronics to automation, due to their balance of durability, versatility, and cost-effectiveness. When engineers and designers seek a housing solution that protects sensitive components while maintaining a professional look, Aluminum Extrusion Enclosure stands out as a smart solution.

In this article, we will explore the functions, performance, and applications of these enclosures. We will also present the technical parameters in a structured format, discuss their importance, and address frequently asked questions to give you a complete understanding of why they are a trusted option.

What Is the Role of Aluminum Extrusion Enclosures?

The primary role of an aluminum extrusion enclosure is to protect delicate electronic devices and systems from environmental damage, mechanical stress, and electromagnetic interference. At the same time, they are designed to provide efficient heat dissipation, keeping internal components stable during operation.

Additionally, these enclosures serve as a foundation for custom designs. With extrusion technology, profiles can be shaped precisely to suit specific project requirements. This flexibility makes them ideal for sectors like industrial automation, communication systems, power supply units, and measurement instruments.

What Are the Key Effects of Using Aluminum Extrusion Enclosures?

-

Enhanced Protection – The robust aluminum structure safeguards electronics against dust, impact, and moisture.

-

Improved Heat Management – Aluminum has excellent thermal conductivity, allowing natural cooling for internal circuits.

-

Professional Appearance – The sleek, anodized surface gives a modern and clean look, suitable for visible installations.

-

Customization Options – Whether through drilling, powder coating, or engraving, enclosures can be adapted to match specific branding or functional needs.

-

Lightweight Yet Strong – Compared with steel enclosures, aluminum extrusion models offer easy handling without compromising strength.

Why Are Aluminum Extrusion Enclosures So Important?

In today's technology-driven industries, housing is more than just a protective shell. It defines how efficiently a system can function under real-world conditions. Using a Aluminum Extrusion Enclosure means:

-

Reliability under extreme conditions, ensuring long-term system operation.

-

Compliance with international safety standards.

-

Easier integration with connectors, PCB boards, and display modules.

-

Cost savings by reducing the need for extra cooling or frequent replacements.

When combined with professional assembly, an aluminum enclosure can extend product lifespan significantly, making it an essential investment for both manufacturers and end-users.

Product Parameters of Aluminum Extrusion Enclosure

Below is a typical technical parameter overview of the enclosures supplied by Ningbo Ruidafeng Electric Co., Ltd.:

| Parameter | Specification | Notes |

|---|---|---|

| Material | High-grade Aluminum Alloy (6063-T5) | Offers corrosion resistance and strength |

| Surface Treatment | Anodized / Powder Coated | Enhances durability and appearance |

| Thickness | 1.2mm – 3.0mm | Adjustable according to project requirements |

| Dimensions | Customizable (length, width, height) | Standard profiles or custom cuts available |

| Protection Level | Up to IP65 | Resistant to dust and light water exposure |

| Thermal Conductivity | Excellent | Natural heat dissipation |

| Color Options | Silver, Black, Customized | Matches corporate branding or aesthetics |

| Accessories | End plates, screws, mounting brackets | Facilitates easy installation and assembly |

This straightforward configuration ensures compatibility with various electronic devices while allowing flexibility for customization.

Where Are Aluminum Extrusion Enclosures Commonly Applied?

-

Industrial Control Systems: To secure PLCs, sensors, and controllers.

-

Power Supply Units: Ensures efficient cooling for transformers and rectifiers.

-

Communication Equipment: Protects routers, transmitters, and receivers.

-

Medical Instruments: Provides a hygienic and protective housing solution.

-

Consumer Electronics: Perfect for small devices requiring both style and safety.

By choosing Aluminum Extrusion Enclosure, companies achieve a balance between high performance and attractive presentation.

Frequently Asked Questions (FAQ)

Q1: What makes an Aluminum Extrusion Enclosure different from a standard sheet metal enclosure?

A1: Unlike sheet metal enclosures, aluminum extrusion enclosures are manufactured using a precision extrusion process. This method produces a seamless structure with superior heat dissipation, enhanced durability, and a more refined appearance.

Q2: Can Aluminum Extrusion Enclosures be customized to fit specific project requirements?

A2: Yes. These enclosures can be tailored in terms of dimensions, surface treatment, colors, and cutouts. At Ningbo Ruidafeng Electric Co., Ltd., we provide customization services to ensure the enclosure perfectly matches your application.

Q3: Are Aluminum Extrusion Enclosures suitable for outdoor use?

A3: With anodized or powder-coated finishes, these enclosures can withstand outdoor environments. Their natural corrosion resistance, combined with optional IP-rated sealing, makes them highly suitable for external installations.

Q4: How do Aluminum Extrusion Enclosures help with heat management?

A4: Aluminum's natural thermal conductivity allows the enclosure itself to act as a heat sink. This eliminates the need for complex cooling systems in many applications, ensuring stable performance even under heavy workloads.

Final Thoughts

Choosing the right enclosure can make a decisive impact on product performance and longevity. An Aluminum Extrusion Enclosure combines strength, heat management, and design flexibility, making it the top choice across industries. Whether you are building advanced electronic equipment, communication devices, or industrial control systems, these enclosures provide both practical protection and aesthetic value.

For more information, technical support, or customized solutions, please feel free to reach out to Ningbo Ruidafeng Electric Co., Ltd.. With extensive experience in enclosure manufacturing, the company is committed to providing reliable and innovative products to meet global market needs. Contact us.